Motion device manufacturers offer a host of positioning tables that can guide or position a load in a wide range of industrial machines. However, some applications present challenges that traditional linear positioning tables cannot address. In this third part of our series on positioning tables, we take a look at some specialized positioning tables, stages and alignment modules available to help designers achieve fast and precise motion for machines with difficult-to-satisfy requirements.

Here are some examples of specialized positioning mechanisms from IKO’s product lineup that are designed to accommodate less-conventional needs:

Alignment tables (AT) can work with both stepper and AC servomotors and incorporate a crossed roller bearing and linear guide to provide precise angular correction, and they can be mounted to a precision positioning table slide for multi-axis applications. One such unit — IKO’s AT positioning stage — features repeatability of ±1 arcsecond.

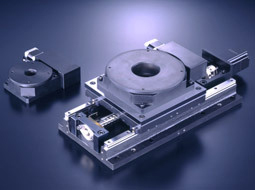

Alignment tables (AT) can work with both stepper and AC servomotors and incorporate a crossed roller bearing and linear guide to provide precise angular correction, and they can be mounted to a precision positioning table slide for multi-axis applications. One such unit — IKO’s AT positioning stage — features repeatability of ±1 arcsecond. Alignment modules (AM), which can be mounted to U-shaped stages, incorporate a rigid crossed roller bearing and linear guide to provide X, Y or X-Y motion, center reference angle compensation or the ability to randomly pivot for angle compensation. Certain alignment modules allow various stage combinations for exceptional design freedom.

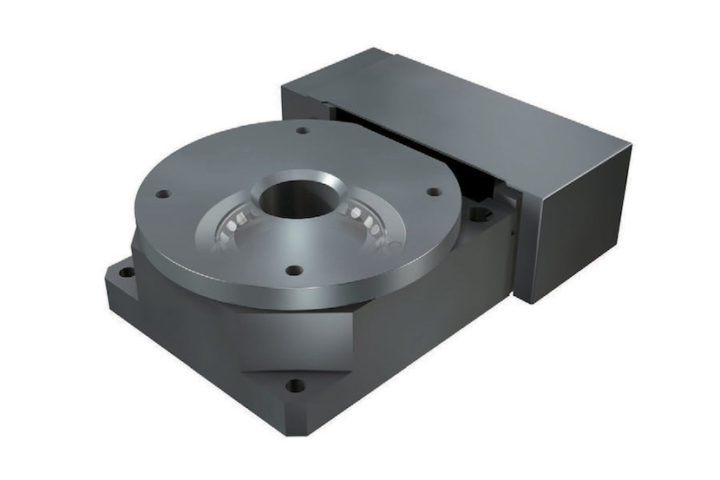

Alignment modules (AM), which can be mounted to U-shaped stages, incorporate a rigid crossed roller bearing and linear guide to provide X, Y or X-Y motion, center reference angle compensation or the ability to randomly pivot for angle compensation. Certain alignment modules allow various stage combinations for exceptional design freedom. Alignment stages (SA) incorporate a crossed roller bearing and linear guide, plus a direct drive linear motor, to provide X-Y-θ positioning with excellent resolution in a low-profile unit. They are well-suited for use with semiconductor and liquid crystal manufacturing equipment as well as positioning mechanisms for measuring and inspection instruments.

Alignment stages (SA) incorporate a crossed roller bearing and linear guide, plus a direct drive linear motor, to provide X-Y-θ positioning with excellent resolution in a low-profile unit. They are well-suited for use with semiconductor and liquid crystal manufacturing equipment as well as positioning mechanisms for measuring and inspection instruments.- Elevating tables (TZ) provide precise up-and-down positioning and, when used with a linear encoder, achieve high repeatability and accuracy thanks to closed loop control. IKO offers elevating stages with a built-in lubrication system called C-Lube which ensures the rolling guides and ball screw achieve long-lasting maintenance-free operation.

- Precision positioning stages are another example of a device that is driven by a stepper motor. IKO’s TSLB Series features a timing belt built into the slide table’s feeding mechanism along with a pair of linear motion roller guides in parallel. Taken together, these components deliver stable and reliable performance for applications requiring high speed and accelerations plus a long stroke length.

- Cleanroom positioning tables (TC-EB) are specifically designed to satisfy ISO Class 3 cleanroom requirements. IKO’s cleanroom positioning tables are lightweight, low profile and compact, and they offer excellent accuracy. Components are made from special materials to withstand harsh conditions, and stainless-steel sheets and side covers prevent dust generated inside the table from escaping into the cleanroom environment. Built-in C-Lube lubrication components provide long life and maintenance-free operation.

IKO Has the Right Positioning Device To Fit Your Needs

Although there are many conventional stages available to address a wide range of applications, specialized positioning tables can be an ideal choice when you need, for example, linear motion at a particular operating angle, precise angular correction or an accurate positioning mechanism for multi-axis applications. IKO has a broad offering of standard linear motor driven and ball screw driven stages plus specialty positioning devices to satisfy most any application, and excellent technical support if you need help choosing the right one.

For more information about IKO precision stages, visit our mechatronics site.