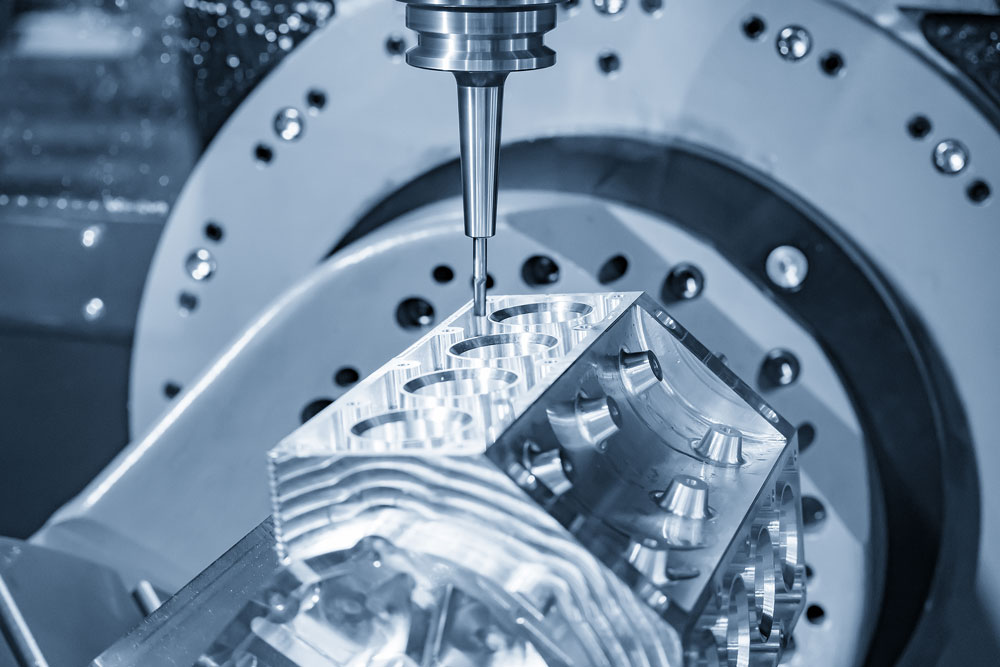

IKO’s broad selection of accurate, durable guides and bearings will help your machine tools

produce quality parts.

Today’s CNC machine tools must address the ever-increasing need for parts made to strict quality requirements. When selecting a motion component for CNC machines, designers must satisfy sophisticated motion needs while also making sure the device delivers accurate and robust operation. Whether you need a motion device to carry heavy loads or to address complex motion needs of multi-axis machining centers, IKO has you covered with a variety of high-accuracy products that can also endure severe use.

Technical Advantages

- Stainless steel and carbon steel construction.

- Corrosion resistant surface treatments including black chrome.

- C-Wiper to protect from dust, metal chips and cutting fluid.

- C-Lube self-lubrication technology.

- Other accessories to prevent contamination.

Application Examples

- Machining centers

- Milling machines—3-axis and 5-axis

- CNC lathes

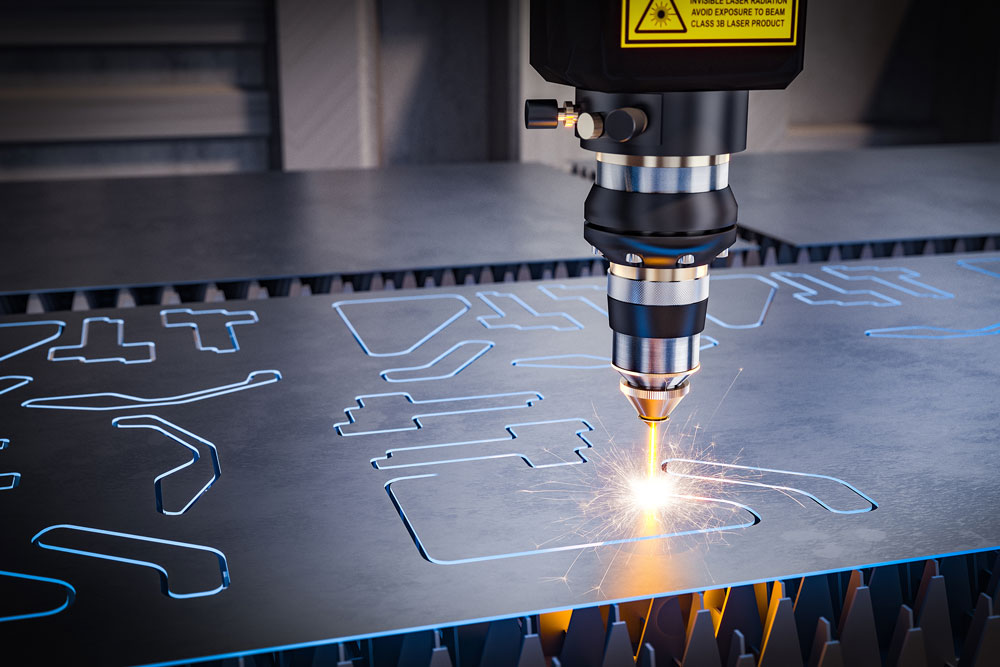

- Grinding machines

- Cutting tools

- Lens polishing machines

Featured Products