IKO’s contamination-resistant motion devices can help improve your food processing operations.

Food and beverage makers’ unyielding effort to improve efficiency and throughput requires precise, reliable operation from motion devices. IKO International’s precision motion products are well-suited for increasingly automated food processes and can withstand the harsh conditions typical in food manufacturing environments while ensuring food safety.

Technical Advantages

- Many products can be supplied with an NSF-approved lubricant that is suitable for incidental contact with food.

- Linear motion rolling guides deliver smooth motion, accurate performance, good rigidity and a long lifetime.

- Many products are offered in stainless steel versions, and IKO can replace plastic components with stainless steel.

- Both ball and roller-type linear motion rolling guides provide stable, accurate operation and excellent rigidity.

- C-Lube products with food-grade lubricant provide long-term, maintenance-free operation.

- Parts can run effectively when wet.

Application Examples

- Cutting machines

- Meat processing machines

- Canning and packaging machines

- Irradiators

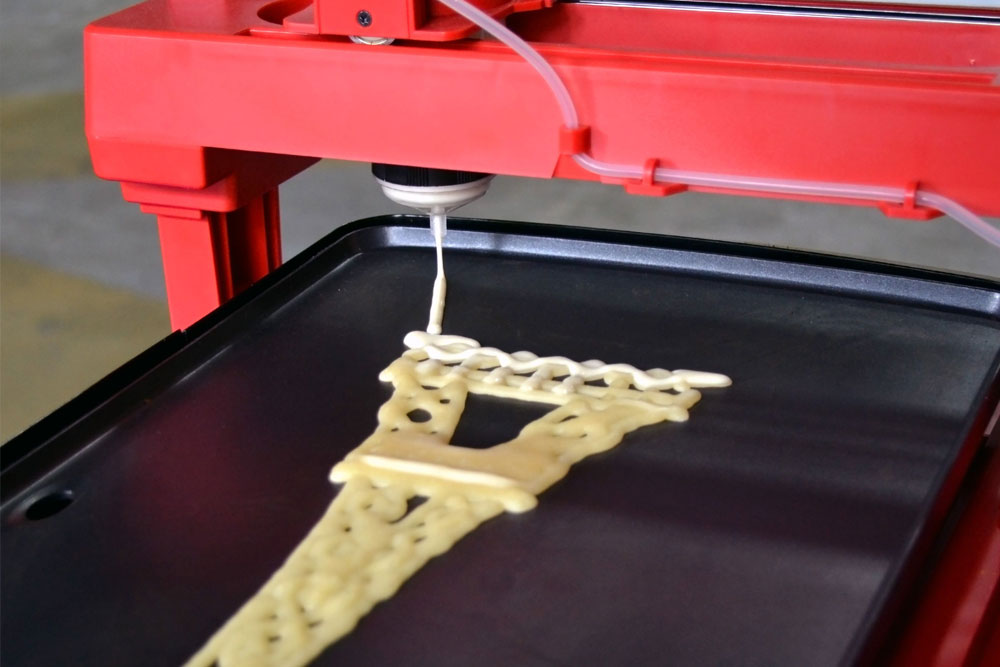

- 3D food printers

- Trim press machines

Featured Products