In an industry where reliability and timeliness are crucial, automotive machine builders trust IKO products for quality and prompt delivery.

The automotive industry knows the importance of staying ahead of the curve. Parts are designed years ahead of a production model, and capital machinery that once took a year to produce is now built in a few weeks. When you need quality motion components in a just-in-time industry like automotive, you can count on IKO.

Technical Advantages

- IKO Reliability. IKO is recognized for reliability wherever capital machinery is used thanks to robust product construction and our commitment to quality.

- Product availability. IKO has a wide range of off-the-shelf motion components and parts available when you need them.

- C-Lube technology. Certain IKO products contain a built-in, self-lubricating element called C-Lube, which reduces maintenance time and expense.

Application Examples

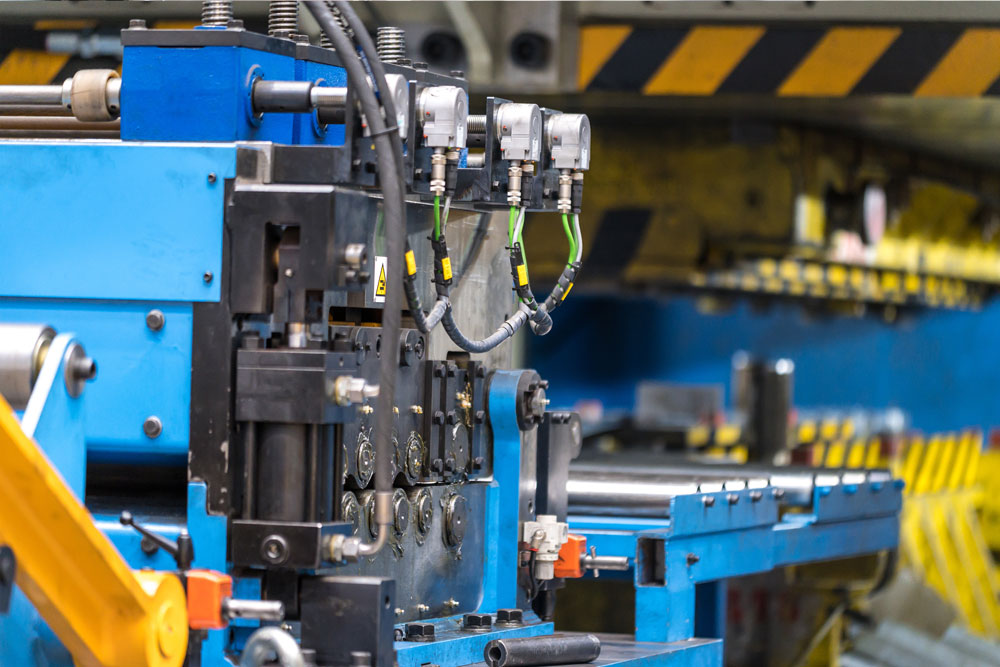

- Stamping plants

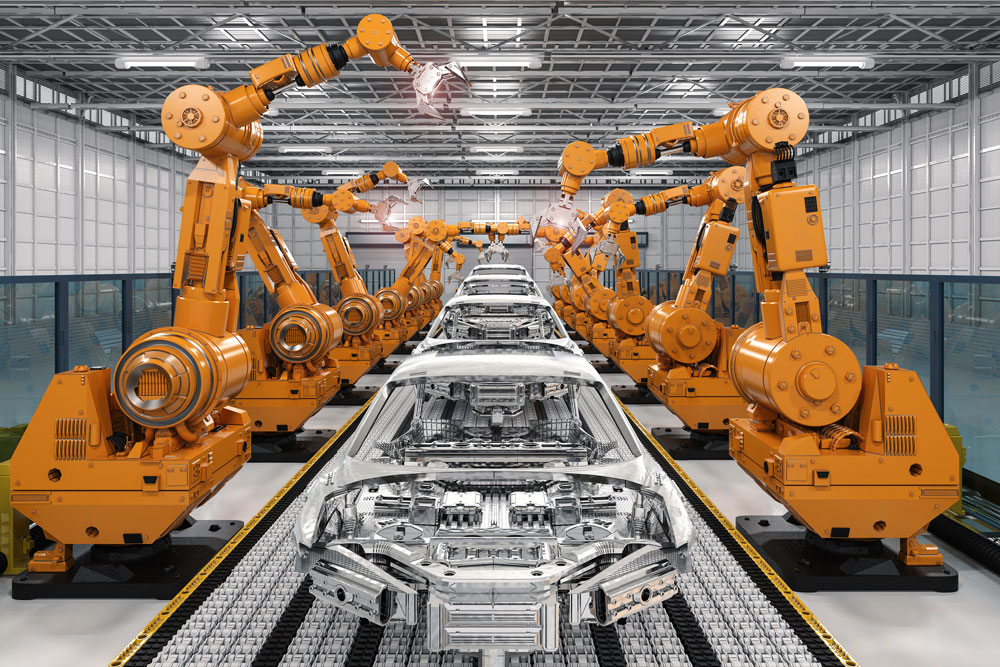

- Assembly fixtures for tooling/molds

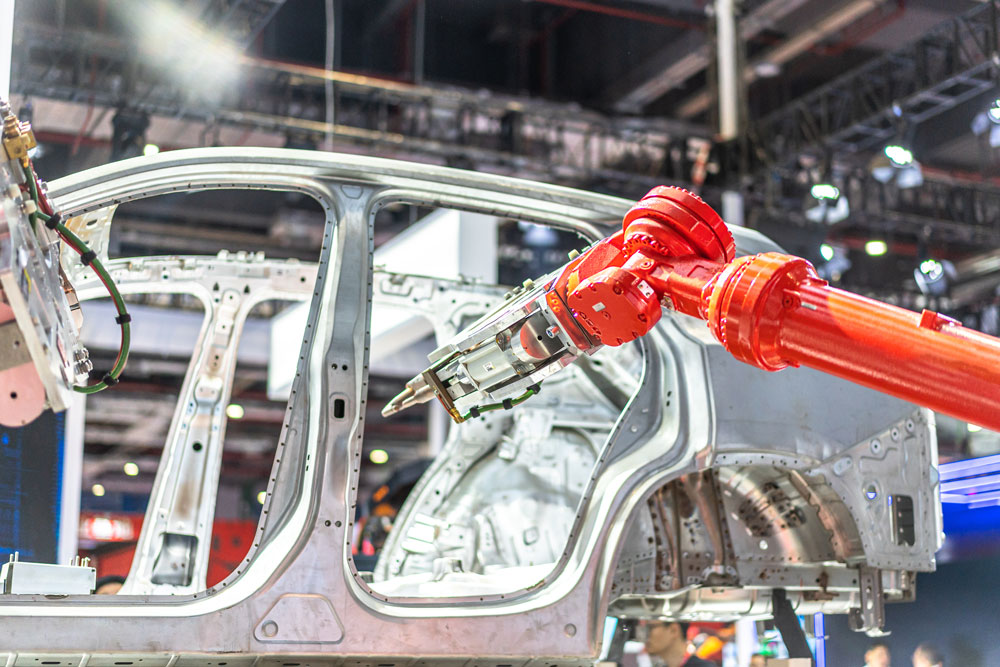

- Welding lines for chassis and frames

- Jigs, chucking and testing fixtures

- Test and measurement

Featured Products