Quality products, prompt delivery and long-term maintenance-free operation help you meet your production goals.

In today’s high-throughput manufacturing environment, OEMs and machine designers must prototype automated equipment quickly and integrate motion components into continually shrinking spaces—all while keeping costs low. We provide quality motion components with prompt delivery to make these challenges easier for designers.

Technical Advantages

- We are recognized for reliability wherever automated machinery is used thanks to robust product construction and our commitment to quality.

- We have a wide range of off-the-shelf motion components and the expertise to help customers fulfill their specifications.

- C-Lube products provide long-term, maintenance-free operation. And since the C-Lube feature is built in, the external dimensions are the same as our standard guides, making them easily interchangeable without any need for redesign.

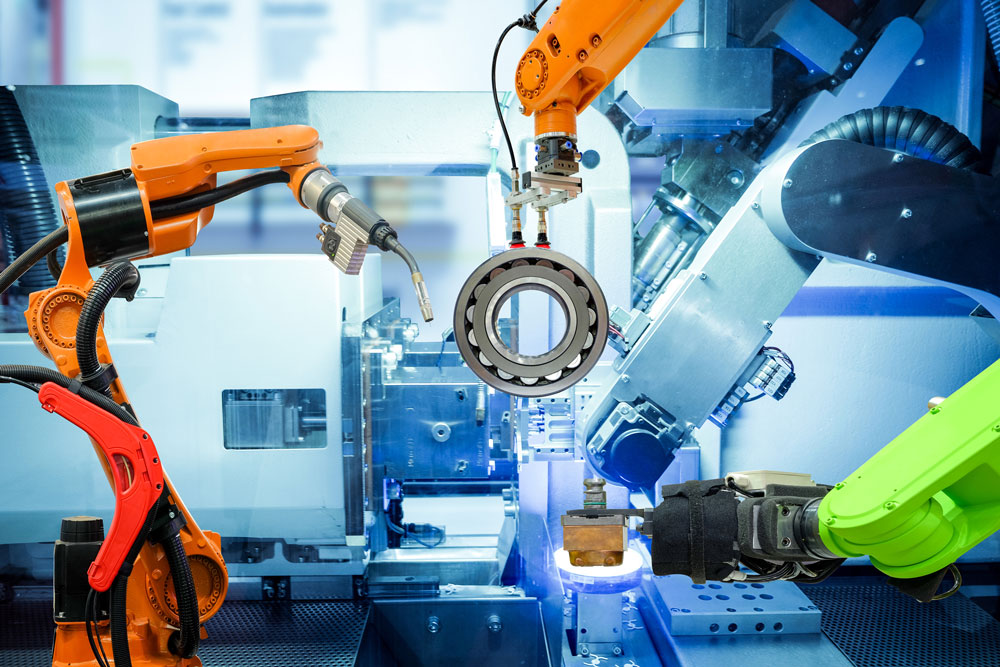

- Crossed roller bearings offer high rotational accuracy and can handle radial, thrust and moment loads at the same time.

- Linear motion rolling guides offer outstanding metallurgical properties to deliver smooth motion, accurate performance, good rigidity and a long life.

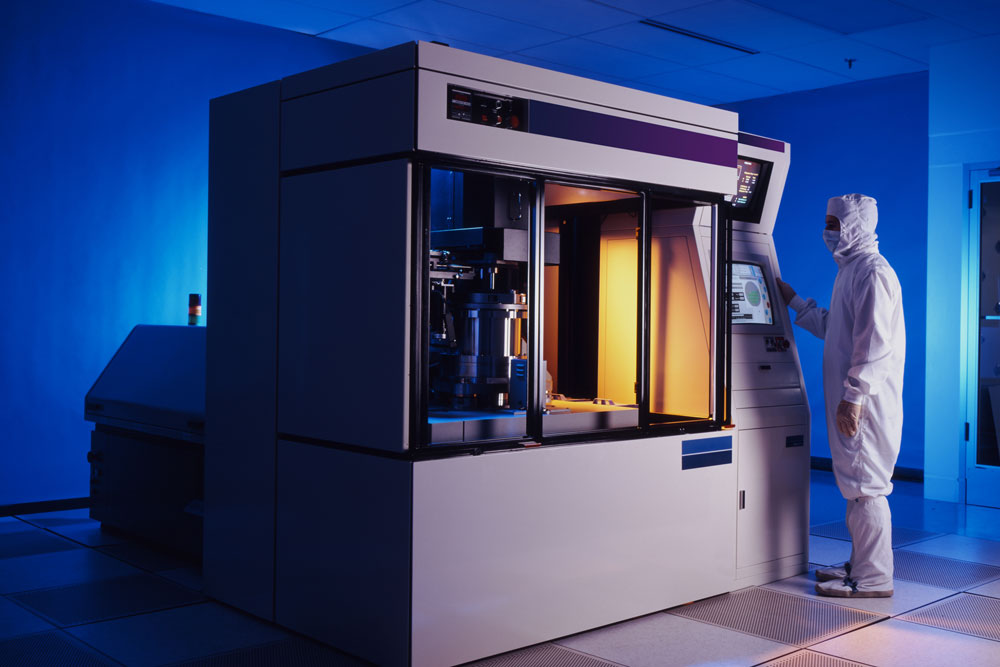

- Many of our products and accessories are offered in stainless steel versions for use in wet or clean room conditions.

- Configurable seals and coatings protect your investment from dust, dirt, grease and other harsh conditions.

Application Examples

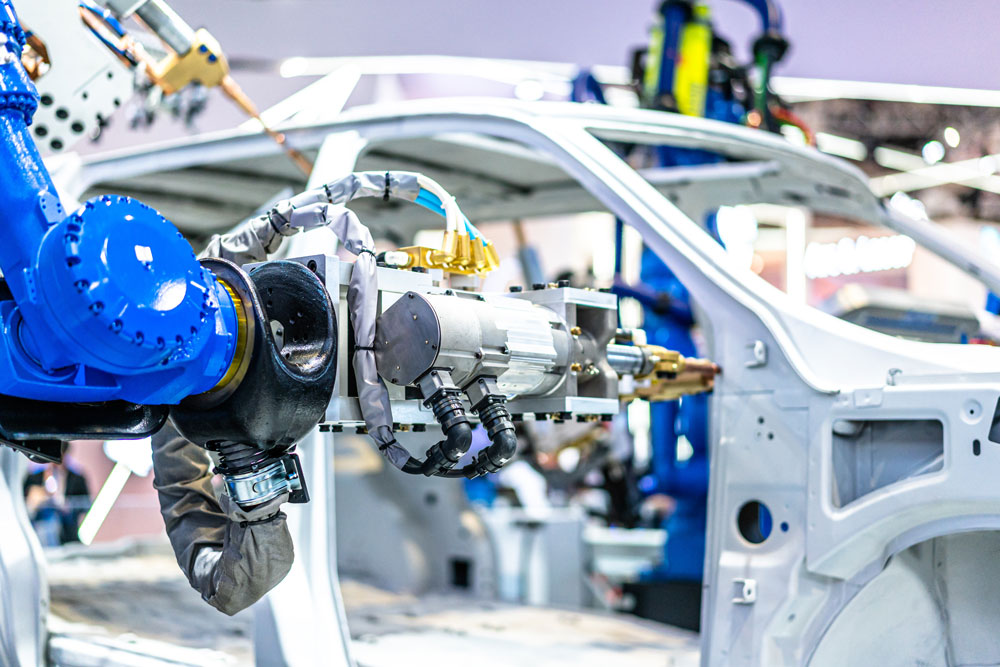

- Automobile manufacturing equipment

- Medical imaging and equipment

- Lab automation

- Electrical appliances

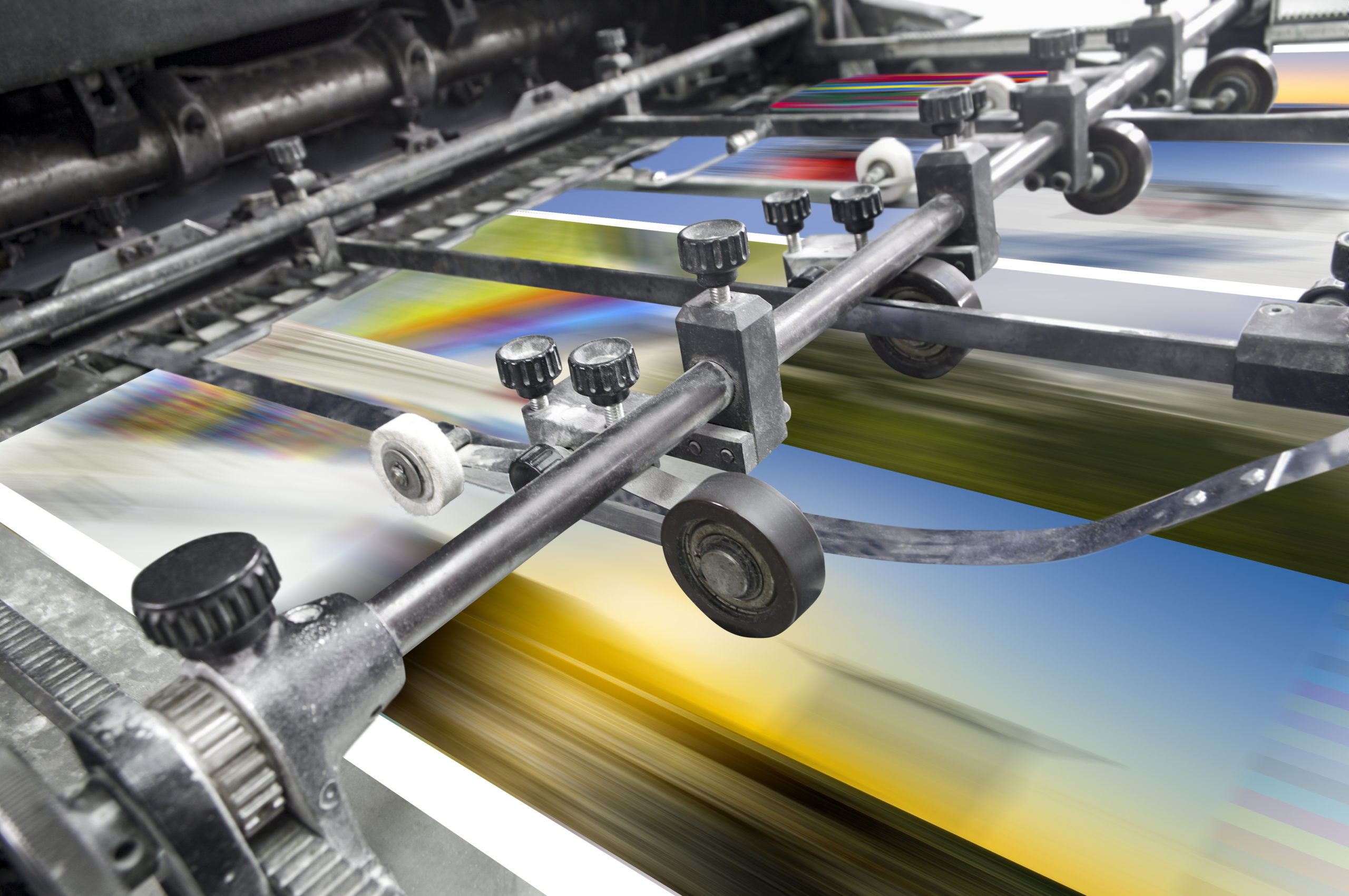

- Printers and presses

- Semiconductor equipment

Featured Products