When you need your cam follower to operate reliably over a long lifetime, lubrication and sealing are critical. In harsh industrial environments, threats such as dust and particles can shorten a cam follower’s lifetime, and heavy use can wear out the bearing’s rolling contact surfaces.

Regular cam follower maintenance comes with headaches. Depending on the application, maintenance personnel may need time to access hard to reach areas in order to re-lubricate a cam follower or they may even need to remove it from the machinery in order to do this maintenance. This could take hours plus the time to reassemble. The result: equipment and plant downtime plus high labor costs. Cam followers with self-lubricating technology can help prevent these headaches and achieve better lifetimes.

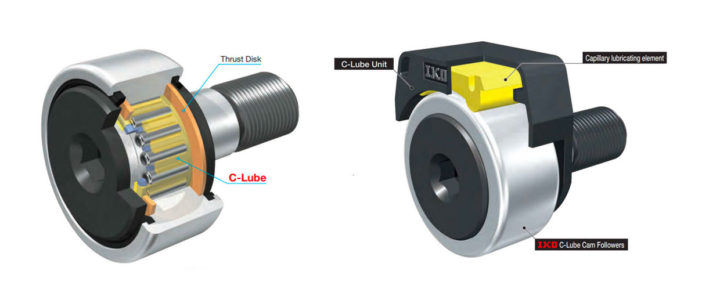

IKO International’s cam follower lineup includes two different self-lubricating options — both utilize IKO’s proprietary technology, C-Lube — that can virtually eliminate maintenance requirements: a cam follower with C-Lube built in and an external unit that lubricates the outer surface of the bearing against the mating track surface.

C-Lube cam followers provide a thermoset solid lubricant that is pre-packed into the bearing space, providing continuous lubrication as the bearing rotates. Since the lubricant is fully impregnated within the unit with extra sealing to prevent particle incursion, it helps extend the device’s lifetime. A smaller radial gap inside the needle roller bearing alleviates load impact to increase its lifetime. Stud diameters are available from 5 to 20 millimeters for this type and series. C-Lube cam followers also offer the same features as IKO’s standard cam followers, such as:

- Small coefficient of friction.

- High rigidity and accuracy.

- Good rotational performance.

- High load capacity.

- Easy installation — simply tighten with a hex wrench.

The external C-Lube unit attaches to a cam follower and applies lubricating oil onto the outside surface of the cam follower’s outer ring and track surface, keeping it properly lubricated. Both the C-Lube cam follower and optional C-Lube unit offer long-lasting maintenance-free operation, reducing the need for costly equipment downtime and labor needed to lubricate the cam follower.

Eliminate Lubrication Burdens and Costs

When it comes to making sure your cam follower will last a long time, lubrication is a necessary but expensive chore. IKO’s C-Lube cam followers and C-Lube units alleviate this burden by continuously lubricating bearing and track surfaces, protecting against harsh operating conditions to lower maintenance costs and to ensure a long lifetime of reliable operation.

For more information about IKO’s C-Lube cam followers and units for cam followers, visit the product page.