Motion system designs that call for a linear guide have variable travel distance requirements. Accordingly, linear bearing manufacturers meet most customers’ needs by offering track rails that can travel the required distance. However, for machines with loads traveling several feet, IKO offers linear guides with long track rails as well as butt-jointed rails.

Butt-jointed rails are a cost-effective option that can help achieve long travel requirements. Machine designers can join multiple shorter-length rails end to end to achieve the long travel distance that sometimes cannot be attained with a single-piece rail. While butt-jointed rails aren’t typically recommended for short travel or for applications that demand the highest precision, they can be attractive for certain situations, such as:

- When you need longer travel. Butt-jointed rails can exceed the longest available rail lengths that a manufacturer may offer.

- When installation space is limited. There are times when a single-piece long guide rail cannot be easily installed in its intended space. However, individual rails that are smaller and lighter can be joined and installed easily within confined spaces.

- When transportation is necessary. Smaller, lighter rails are easier to transport. For example, compared to long single-piece rails, butt-jointed rails can be broken down easily into smaller, lighter sections for both trouble-free transport and easier reassembly at the customer’s site.

- When you want to keep costs low. Because applications that require longer travel lengths are less prevalent, linear guides with longer rail sizes often come with a higher price.

- When you need it fast. IKO International stocks off-the-shelf linear guides in a variety of sizes at multiple U.S. locations for quick delivery. Not only can you install smaller, lightweight rails quickly and easily, chances are you’ll receive them sooner than a longer, single-piece unit and get your machine up and running faster.

If a butt-jointed rail assembly is among your potential solutions when you want to achieve long linear travel, you can count on IKO products for performance and reliability. Although single rails offer smoother travel, the construction and internal geometry of our linear motion guides help compensate for reduced travel smoothness during the transition between rails. And, when installed correctly, butt-jointed IKO rails are as reliable as our single rails. You can also use butt-jointed rails with our C-Lube slide units for long-lasting, maintenance-free operation.

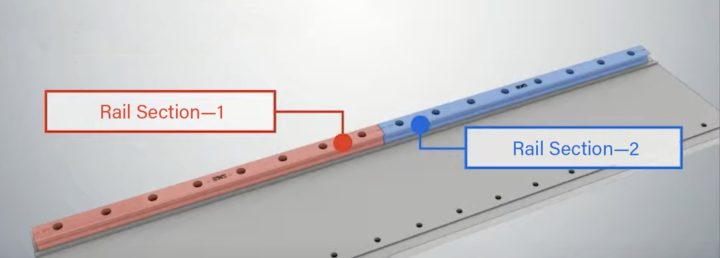

IKO also offers track rail sections with a butt-joining mark on the top surface to help make identification and installation easier.

Achieve the Travel Length You Need

For applications that must carry a load far, long single-piece rail guides can extend to great lengths. However, in certain applications, butt-jointed rails may be a suitable alternative to single-piece rails — especially when the project involves challenges like limited installation space, budget, availability and transport. IKO offers reliable, high-performance linear products that can be adapted for butt-jointed rail assemblies, and our technical staff is ready to review your options to help you achieve the travel length you need.

To learn about installing butt-jointed rails, watch our video.