Machine designers have come to rely on roller type linear motion rolling guides for their excellent load handling, accuracy and rigidity. This type of guide is able to deliver these benefits because their slide units contain multiple rolling elements which create a larger contact area with the rail surface than ball-type guides. However, some applications can demand performance over and above what standard linear roller motion guides can provide.

One way to improve the performance of linear roller guides is to reduce the running deflection. During travel, the movement of the slide unit can cause repeated pulsations in a vertical direction. These fluctuations can affect the guide’s accuracy and smooth motion. IKO International offers a special specification for its C-Lube Linear Roller Way Super MX series that suppresses small running deflections and fluctuations when used with industrial machines requiring highly precise linear motion.

Low-Deflection Linear Guides Provide Multiple Benefits

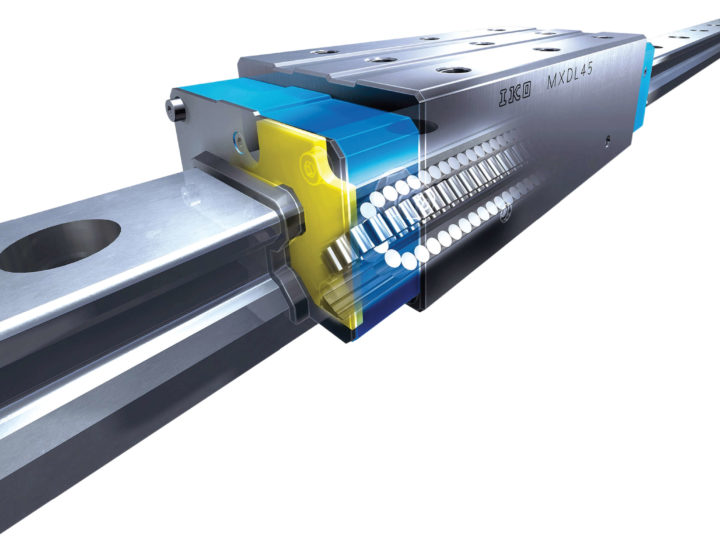

The IKO C-Lube Linear Roller Way product family provides the high-performance features machine designers expect from linear roller guides along with long-term, maintenance-free operation. The Super MX Master Grade low-fluctuation model is ideal for applications like machine tools which demand excellent rigidity for handling large, heavy parts yet still need a high level of precision.

Super MX Master Grade units are best suited for applications requiring:

- Low fluctuation.

- Maximum rigidity.

- Increased load capacity.

- High precision.

- Long-term, maintenance-free operation.

IKO International’s C-Lube Linear Roller Way Super MX Master Grade guides boast several performance advantages that set them apart from other linear motion devices:

- Small running deflection. The roller raceway surface with improved performance suppresses the running deflection, and it reduces fluctuation by approximately 50 percent compared to standard extra-long units. Testing has shown that Super

MX Master Grade guides exhibit a running deflection value within 0.0090 µm (9.0 nm). - Low fluctuation. The Super MX Master Grade’s low fluctuation characteristics result in steady, smooth travel for demanding, high-precision applications.

- Extra-long slide unit. Because more rollers are built into the slide unit, load capacity, rigidity and running performance are optimized for machine tool and semiconductor manufacturing, and any other type of mechanical device requiring

high precision. - Long-term, maintenance-free. IKO’s C-Lube self-lubricating system uses a built-in capillary element to provide long-term, maintenance-free operation while minimizing the amount of lubrication required and the associated expenses.

The C-Lube Linear Roller Way Super MX Master Grade guide is available in various load capacities and mounting configurations. The supported models are: MXL, MXDL, MXSL, MXNL and MXNSL.

The Best of Both Worlds: Accurate Linear Motion and Reduced Fluctuation

Designers of machine tool and semiconductor manufacturing equipment can realize high precision while managing deflections that can cause vertical fluctuations.

IKO International’s C-Lube Linear Roller Way Super MX Master Grade series combines the excellent load handling, rigidity and accuracy that characterize roller-type linear guides with the ability to suppress small running deflections, while providing

long-term, maintenance-free operation.

For more information on IKO International’s Super MX Master Grade Linear Roller Way, download our brochure.