In many machine building applications, engineers face limitations in how they can integrate cam followers into their design–an issue that often boils down to ease of mounting the cam follower.

When mounting is an issue, it’s important to consider the following when selecting your cam follower:

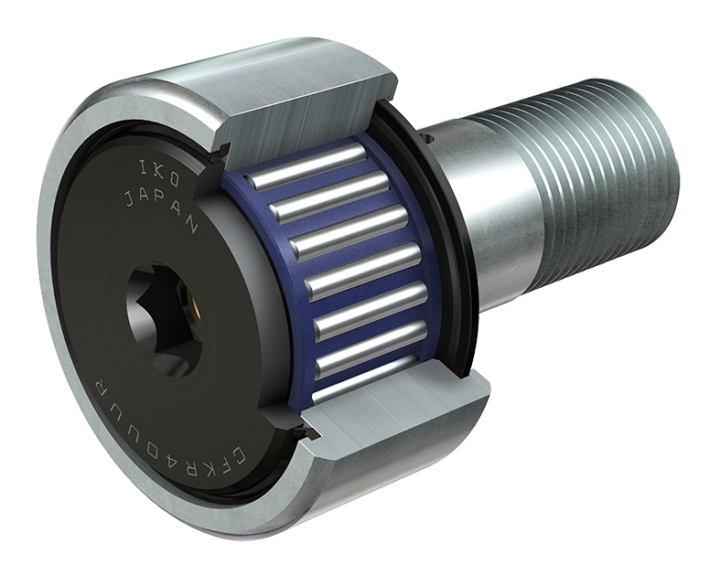

- Double hex hole design. Cam followers, like our CFKR model, feature hexagon holes on both stud ends, letting you easily mount them with a hexagon wrench from either side. You can therefore install them in tight, hard-to-reach spots

on your machine and then tighten them from the opposite end. With this design, the mounting options are limitless. - Design flexibility. Having a wide range of design and size options matters if you want to maximize the performance of your linear bearings. CFKR cam followers are available in sizes as high as 90 mm roller diameter, depending on your

application. Also, be sure to look for variations in roller guide method (cage or full complement), shape of the outer ring outside the surface (crowned or cylindrical) and seal structure (shielded or sealed type). We also have an Easy Mounting Type cam follower that is somewhat unique to IKO and allows for additional design flexibility.

- High load ratings. Too many linear bearings on the market today are limited in terms of the loads they can bear. CFKR bearings, however, demonstrate superior rotational performance and high load capacity. Consider the CFKR 90 V model,

which features dynamic and static load ratings in excess of 67,000 and 144,000 N, respectively, compared to 40,500 and 83,000 N for similar cam followers on the market.

You can learn more about our CFKR line of cam followers here.