Not long ago, the motion systems used in medical and lab automation equipment had technical requirements that were easy to satisfy. These lightly loaded applications generally required simple point-to-point moves with low to moderate positioning accuracy requirements.

With the exception of surgical robots and some diagnostic systems, many medical machines still have modest positioning accuracy requirements compared to applications such as semiconductor and electronics assembly. Yet the motion axes in medical machines have to run smoothly, quietly and sometimes at high speeds.

Medical motion systems have therefore had to become more sophisticated to keep pace with two unfolding trends in the medical machine marketplace:

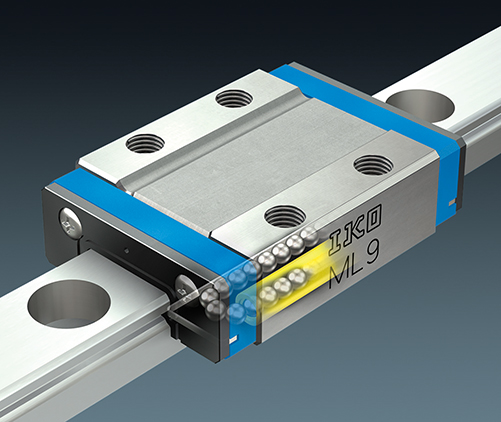

- Miniaturization. Diagnostic equipment, DNA sequencers and other types of automation systems occupy less space than in years past, and these machines increasingly require streamlined mechanical designs.

- Increasing demand for reliability and low cost of ownership. Linear guides can make a big difference in how well the machine runs and how much it will cost to keep running.

The next generation of medical machines will need linear guides that are compact relative to the loads they carry. They will also need to run smoothly with adequate precision and integrate design features that ensure the machine has a long, trouble-free

life.