Walk through any plant that uses linear motion systems, and you can often see maintenance workers, grease gun in hand, applying lubrication to linear guides. And why shouldn’t they? Under-lubricated guides can wear excessively, which leads to performance problems and premature failure.

These labor-intensive lubrication practices, however, do not come cheap. Manual lubrication can cost upwards of $500 per grease fitting when you consider:

- The cost of the lubricant itself.

- The wages of the guy with the grease gun.

- The fact that many grease fittings are difficult to access and service without triggering some downtime.

But it doesn’t have to be that way. There are a number of linear guides that offer at least some freedom from lubrication routines. These typically have mechanical designs with provisions for storing and delivering lubricant over long periods of time.

While various takes on maintenance free guides and ways have been around for years, not all of them are created equal. Some focus on achieving the longest possible maintenance-free intervals. Others focus on a compact design that adds as little as possible to the size of the bearing’s mechanical package.

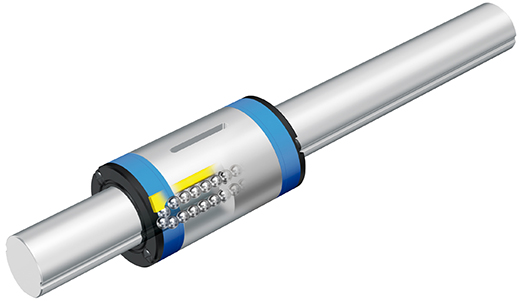

C-Lube linear components have unique designs that balance long service life with compact size. Depending on the functional requirements, these long-term maintenance free linear motion products come in different forms—including roller guides, ball guides and a ball-spline-based shaft guiding system.

To learn more about our different C-Lube variants, download the white paper.